The smart Trick of Digital Printing That Nobody is Discussing

Table of ContentsSome Of Digital PrintingDigital Printing Things To Know Before You BuyExcitement About Digital Printing

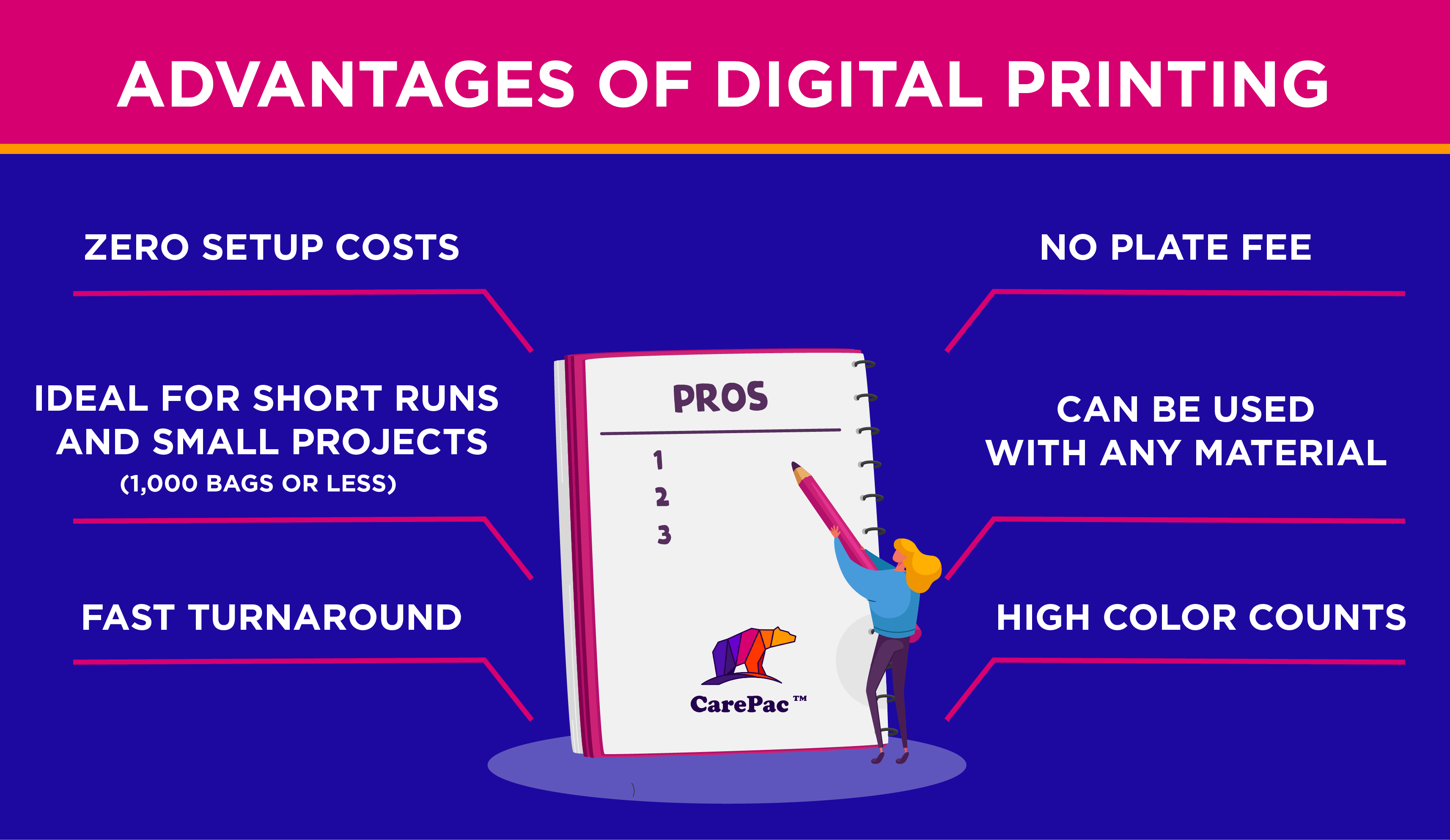

The liquid ink adheres to the substratum through an electrostatic charge, making sure vivid colours and sharp information. Digital printing also calls for marginal arrangement. Although modern-day lithographic innovation has actually decreased setup times to around 15 mins, electronic printing still leads to convenience with its near-instant preparedness. Furthermore, digital prints completely dry instantaneously, unlike lithographic prints, which need 2-3 hours to dry. This eliminates smearing risks and the requirement for drying shelfs. Below are the vital ways in which digital printing sustains greener practices: One of the substantial environmental benefits of digital printing is lowering waste. Conventional printing methods, like lithographic printing, commonly waste substantial quantities of paper and ink during the arrangement stage. Digital printing eliminates the demand for plates and other consumables, lowering waste throughout the manufacturing process. A few of the most typical applications consist of: Digital printing is perfect for producing calling card, leaflets, posters and other advertising materials. It permits fast turnaround times and economical manufacturing, especially for organizations with smaller print runs. Digital printing is progressively used in the product packaging industry to create distinct, custom-made product packaging.

Digital printing presses eliminate the need for these plates, substantially minimizing setup prices. Digital printing presses can include variable data into your prints, which enables extremely customized advertising materials (Digital Printing). By customizing your advertising and marketing products, you can boost involvement with prospective customers and boost the opportunities of converting them into actual customers

Digital printing machine supply superb shade consistency and precision, resulting in better prints. With electronic printing, you can be certain that the color of your prints will correspond from one print work to the following. A number of years earlier, several customers did decline direct-injection digital printing since the high price. The acquisition cost of a set electronic printing tools is at least 150%of the traditional printing and coloring equipment, which boosts the.

Some Of Digital Printing

In order to protect against corrosion of the nozzle, the ink for digital printing is much more expensive than the ink for traditional printing, and additional ink purification is needed throughout the printing procedure. In electronic inkjet printing, the pattern is directly printed on the material, getting rid of the plate making in rotating display printing. Yes, are more costly than traditional printing inks, but the electronic printing procedure can conserve ink usage.

Today, the electronic direct-injection printing press has gone from proofing to the phase of medium-sized and large-sized production. The electronic direct-injection maker has actually experienced the promotion period and went into the development and maturity period. Both printing residences and brand proprietors understand the advancement potential of electronic printing, and are eager to increase investment in electronic printing. The print top quality can sometimes also competing that of balanced out printing. Digital printing is more affordable for short print runs due to the fact that it calls for less pre-press activities and much less configuration than offset printing. If an error in countered printing is not captured before home plates are made, it will be extremely pricey to make click for source brand-new ones. While every person genuinely hopes that errors will be avoided, it is sensible to prepare for their prospective modification. Furthermore, its precision is extremely high. This makes sure uniformity in look across the board, lowering the likelihood that any type of item will need to be thrown out as a result of defects. Making certain the plates are in place, the ink trick is calibrated, and all the necessary changes have been made is a taxing process when countered printing. Minimized pre-press steps suggest less time is needed to establish journalism at first. This leads to a significant acceleration of turn-around time. When you require printed materials promptly, this is a wonderful option. Digital printing can be a lifesaver when you obtain an order at the last minute.

Variable information printing, such as direct mail with personalized codes her explanation and addresses, is ideally suited for electronic printing. Digital fast printing just needs 4 actions of style, evaluation, printing and binding to get every little thing done. Digital fast printing has an exceptional benefit: print on need.